Jellagen and Copner Biotech complete world-first SMART Cymru-funded project supporting the development of a next-generation bioprinting system and bio-ink.

29 September 2022

- Jellagen and Copner Biotech have successfully completed a world-first 3D bioprinting project after receiving a SMART Cymru innovation funding.

- Copner Biotech has developed a next-generation, high-precision bioprinting software, and hardware platform.

- Jellagen has harnessed the potential of an ancient jellyfish species to develop technology supporting bio-ink applications that can be combined with Copner Biotech’s 3D printer technology to advance tissue engineering.

Jellagen Ltd, are proud to announce the successful completion of their innovative, collaborative SMART Cymru project, led by Copner Biotech, focused on developing new tissue engineering technologies through creating a prototype bioink using novel jellyfish-derived Collagen Type 0 combined with Copner Biotech’s high precision, bioprinting system.

Bioprinting is a process that aims to build fully functioning tissues and organs using biomimetic (man-made) materials and living cells. Bioprinted materials, therefore, have applications for both research and tissue engineering. Current bioprinting systems on the market are limited, with dated software protocols, often using mammalian sources of biomimetic materials and living cells, which have multiple ethical safety and religious implications.

Jellagen’s prototype technology has shown exciting potential to be used as a bio-ink by using their proprietary next-generation biomaterial, Collagen Type 0, a jellyfish-derived source of collagen. Collagen Type 0 is harvested from Barrel Jellyfish in the Irish Sea, which are becoming vast blooms of marine pests surrounding the coast of the UK, threatening biodiversity. Being at the root of the evolutionary tree, jellyfish-derived Collagen Type 0 is far purer, safer, more efficacious, and versatile than its mammal counterparts.

Professor Andrew Mearns Spragg, Founder and Chief Scientific Officer of Jellagen comments,

“Although not yet commercially available, SMART Cymru’s funding has enabled a world-first partnership in 3D bioprinting with Copner Biotech. We are delighted with the data outputs of this project that has clearly demonstrated the further potential use of our Collagen Type 0 biomaterials for future bio-ink development. We are very excited to see how this technology can be further developed towards medical tissue engineering applications and cell culture research market solutions.”

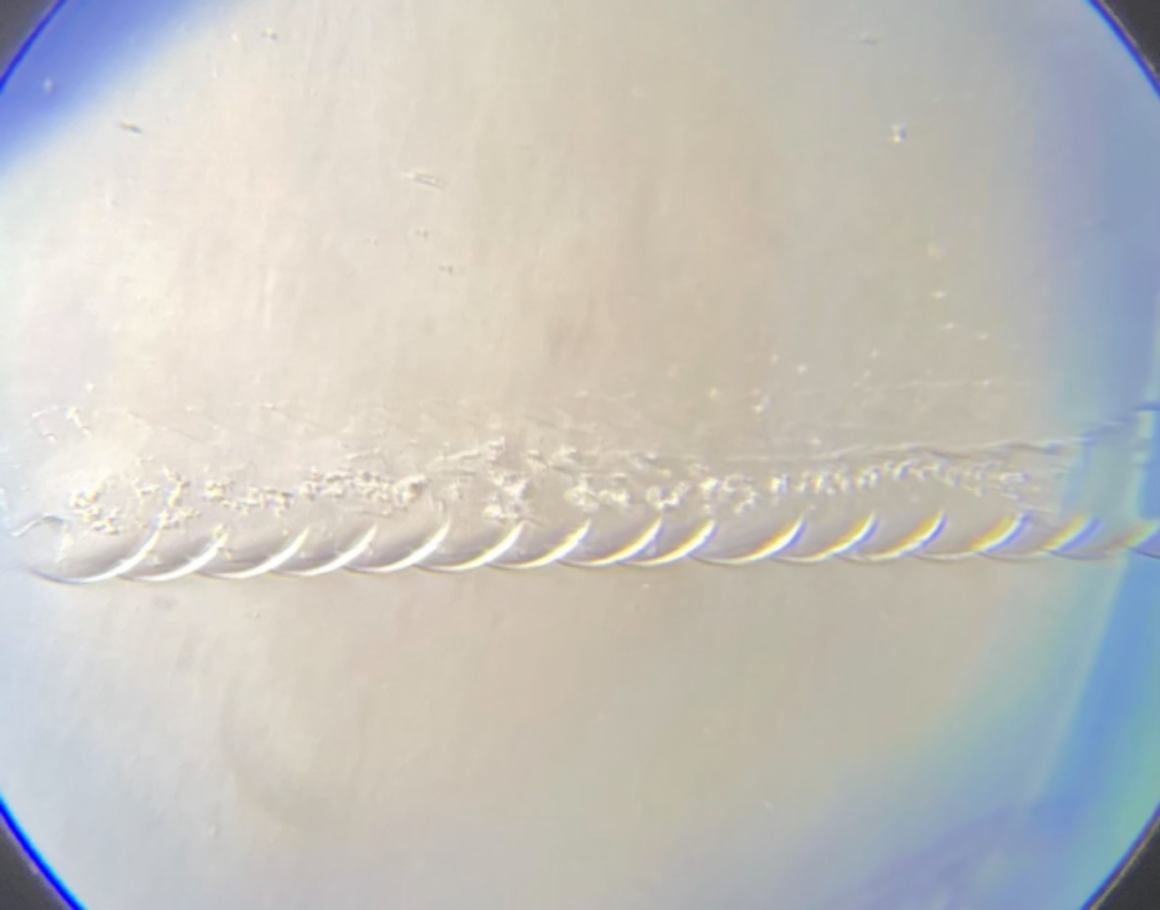

Throughout the SMART Cymru-funded project, Copner Biotech’s innovative and disruptive bioprinter, the GRAPE-S1, was able to successfully print very fine (<100um in diameter) 3D structures using Jellagen’s novel hydrogel technology as a bio-ink platform. This demonstrates an important and unique feature of the ink, as when combined with the GRAPE-S1 technology this allows for precise 3D architecture to be modelled that could potentially efficiently mimic the micro-environment of a living system. Jellagen’s prototype bio-ink itself boasts additional ranges of characteristics, including the ability to quickly develop strong, long-term scaffolds. Moreover, the GRAPE-S1’s approach to bioprinting with precise, next-generation software control, has given rise to high consistency printing of complex architectures. This is of particular importance in bioscience research, for the creation of multiple reliable 3D cell culture models.

Jordan Copner, Founder and CEO of Copner Biotech added,

“3D bioprinting has huge potential to transform lives through tissue engineering, and through this latest partnership with Jellagen, we are excited to be able to show the potential real-world benefits of this technology.”

Copner Biotech has now secured orders for their bioprinter prototype in the UK via the ‘Early Adopters Program’. This program allows researchers to obtain next-generation bioprinting hardware and software at incredibly competitive prices, in return for direct feedback and optimisation information.

Jellagen is now further developing and refining its bio-ink platform technologies suitable for additional 3D bioprinting applications in medical tissue engineering and research market applications.

About Copner Biotech

Copner Biotech Ltd was founded in 2020 with the vision to disrupt the 3D cell culture market with innovative technologies. The 3D cell culture space has the potential to further important medical research with real world benefits, such as cancer research and tissue engineering. Copner Biotech’s goal is to design, create and utilise new software platforms to manufacture competitive products for the 3D cell culture market.

As a company we have celebrated several successes to date, including the development of a novel software operating platform for the design of cell culture scaffolds that encourage oxygen and nutrient gradients and the presentation of the GHP International Life Sciences Award for Innovation 2021. Our mission now is to develop further upon what we have already created and commercialise it via the mass manufacture of polymer cell scaffolds and bioprinting products.

About SMART Cymru

SMARTCymru supports Welsh businesses to develop, implement and commercialise new products, processes, and services. It does this by co-investing in Research, Development, and Innovation projects that help to deliver sustainable growth

The scheme, which is part funded by the European Regional Development Fund, can assist businesses at every stage of their Innovation Journey, from Feasibility, through Industrial Research and Experimental Development, and on to Exploitation support. The scheme can also support the costs of implementing new processes. SMART Cymru has supported more than 400 businesses in Wales to develop over 500 innovative projects.